Dry Cooling 101

What is dry cooling?

Dry cooling removes heat from a system using ambient air for heat rejection. The lack of water and any need for water treatment greatly reduces the required maintenance for this type of cooling equipment. Dry cooling can be used for closed circuit cooling of fluids and also for steam condensing. Please contact your local EVAPCO representative or reach out to us directly to learn more about EVAPCO's Dry Cooling technologies.

Application in Steam Condensing

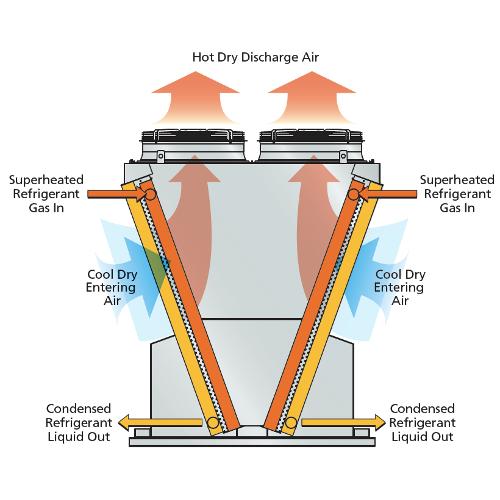

Dry cooling is widely used as a method for vacuum steam condensing in power generation using an Air Cooled Condenser (ACC). In this process, steam exhausts under vacuum from the outlet of a steam turbine into a series of round ducts which transport the steam to the ACC. The ACC directs the steam through an array of finned tubes where ambient air is forced over the fins resulting in condensation of the saturated steam. In short, the ACC is comprised of ducting (to transport the steam), heat exchanger cores (finned tube bundles) to facilitate heat transfer, mechanical equipment to create airflow (fans, motors and gearboxes) and piping/tanks to collect the condensed steam. The below schematic highlights these items:

An Air Cooled Condenser can replace a surface condenser and cooling tower system when water is not available or simply too expensive. If you are considering an ACC for a vacuum steam condensing application please contact Evapco so we can start custom engineering a solution for your project.

Application in Closed Circuit Fluid Cooling

Air flow and surface area are key to maximizing the effect of dry cooling. EVAPCO facilitates this transfer of energy by running process fluid through a series of highly conductive aluminum fins. By constantly drawing large quantities of air through the fins, heat is quickly removed from the system and discharges to the atmosphere.

EVAPCO offers several models designed specifically to run in 100% dry cooling mode as either closed circuit coolers, or condensers; we are proud to offer these units as part of our global initiative to provide sustainable products and services to the cooling industry.

eco-Air Titan

EVAPCO's eco-Air Titan offers a reduced footprint and lower auxiliary power requirements compared to traditional fin fan coolers.

eco-Air ACHE

EVAPCO's eco-Air coolers maintain a low profile while providing effective dry cooling capabilities. With a wide range of available arrangements, fan types and accessories, the eco-Air line of coolers are a highly customizable, shop-assembled option that will meet the needs of any project. Our latest eco-Air development is the Double Stack ACHE with a second tier of heat exchangers for twice the cooling capacity.

EVAPCO’s numerous patents and trend-setting technologies demonstrate our tireless pursuit of innovation; we are constantly investing in research and development to improve our products and the experience each of our customers has with our cooling solutions. Choosing EVAPCO is choosing progress.